Tubes are the essential building blocks whether you're making equipment for gyms or for smaller, multifunctional exercise devices for your home. This is why so many technologies for tube processing, like bending and laser-cutting, are widely used within this sector.

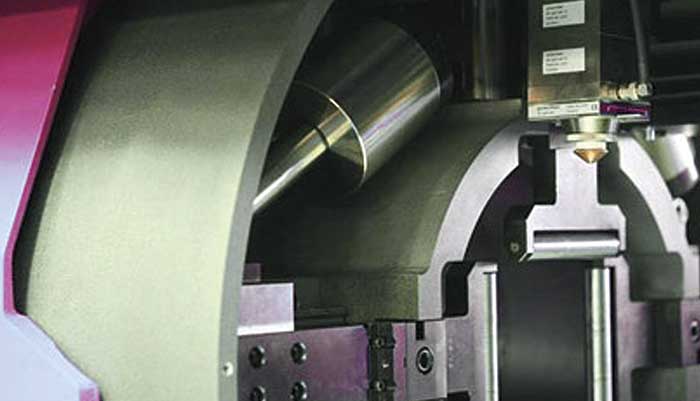

You may have noticed we haven’t covered cutting speed. Although you can cut up 500 inches per minute using a tube cutter, it's not always practical. Laser tube cutting involves focusing on the time required to load a tube, index the tube so it's in a good position for cutting and then pierce, cut and unload the part. It is not about cutting speed, but part-processing time when laser tube cutting machines are used.